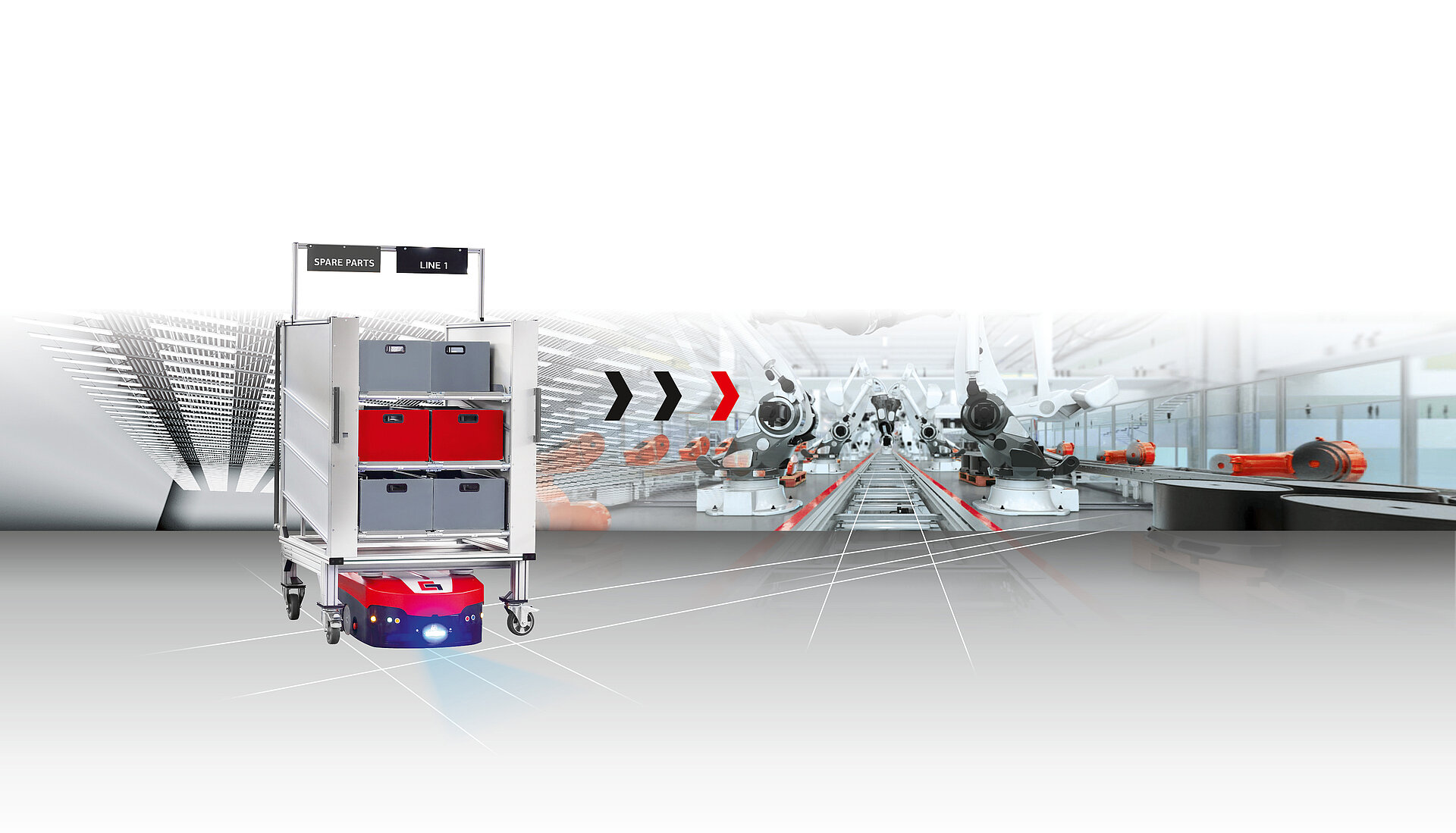

Maximum efficiency and safety for your material flow

Grenzebach Intralogistics Solutions for the Automotive Industry

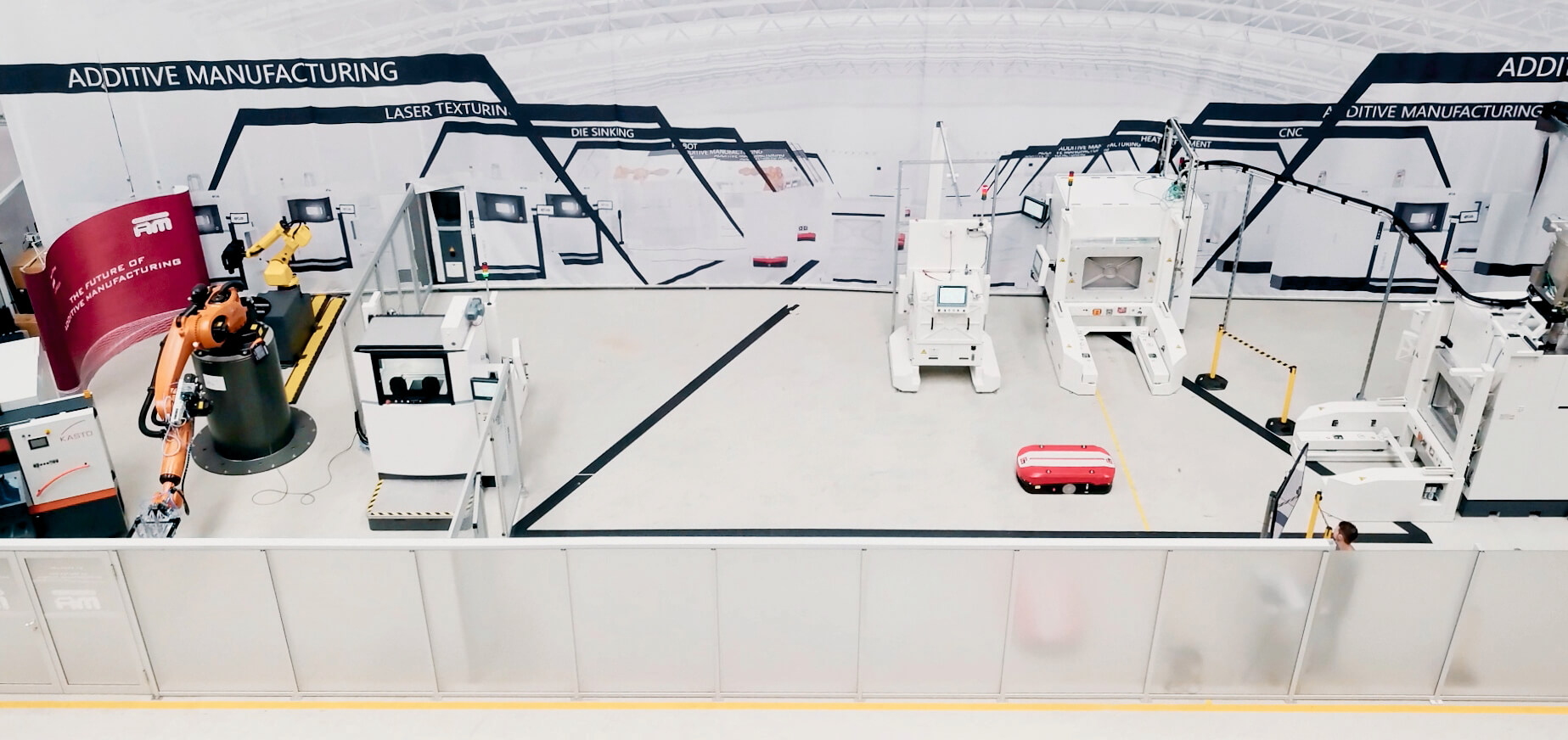

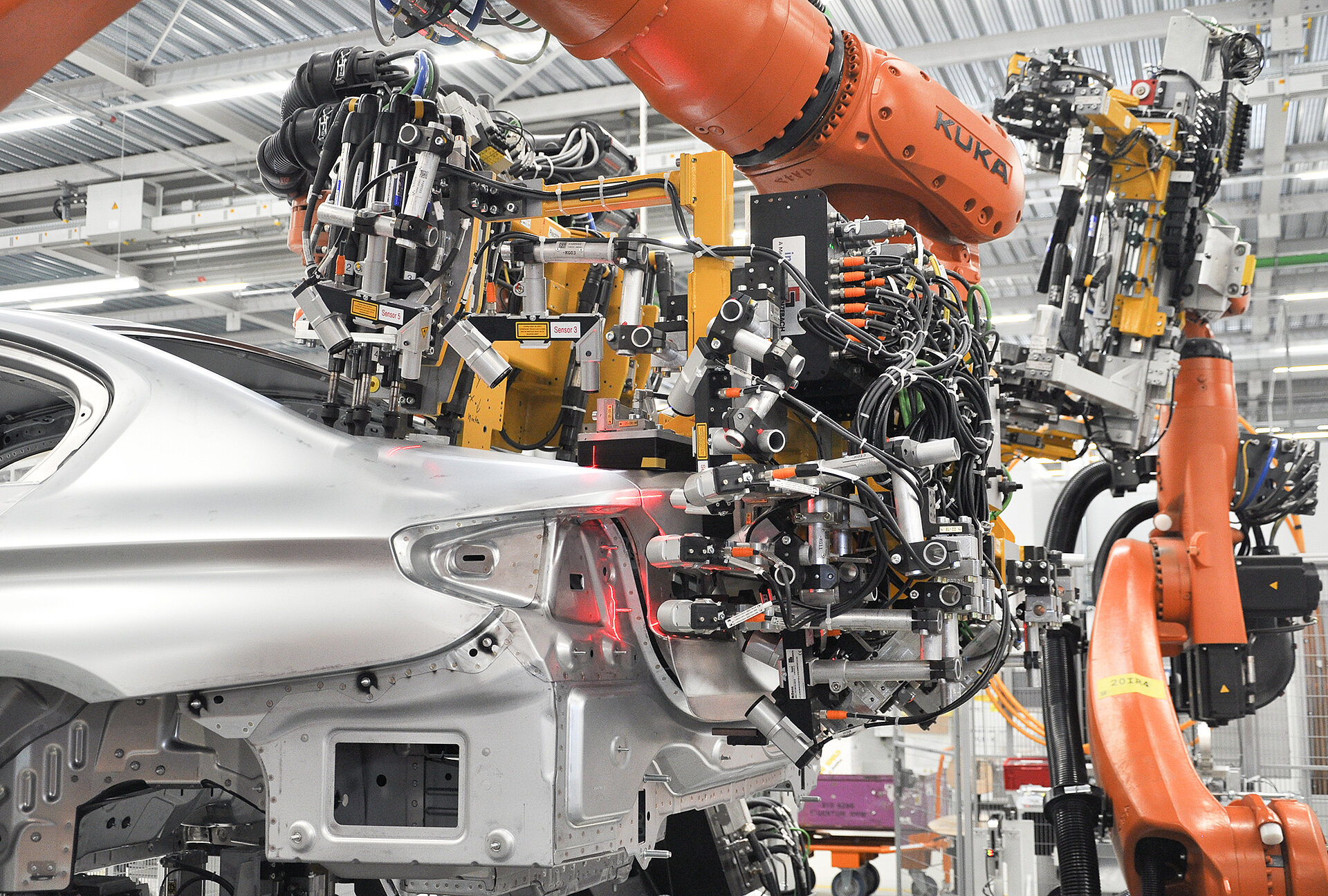

Grenzebach’s intralogistics solutions literally move you forward. Whether providing components for just-in-sequence production or solutions for (small) parts picking – our award-winning systems enable efficient, reliable production with maximum flexibility.

Our approach: holistic solutions tailored to your needs, including hardware, software and service. Rely on our 60 years of experience in the automation of industrial processes and our expertise in the automotive industry.

You too can benefit. Your advantages:

Efficient material flow

You benefit from shorter, more predictable cycle times, as well as high reliability for just-in-time or just-in-sequence deliveries.

Faster response

Thanks to the high level of integration with existing systems, it is possible to respond more flexibly, faster and more predictably in critical processes than with a classic intralogistics solution.

Flexibly adaptable

The solutions can be implemented easily in existing environments and can even save space. Elevators, robot cells, conveyors or strapping systems can be integrated. And if your production process changes, the solution is flexible and easy to adapt.

360° Added Value. The new OL1200S.

More autonomous, quicker, smarter and developed for special requirements in the automotive industry: The new automated guided vehicle OL1200S is our specialist AGV for long load carriers and payloads of up to 1,200 kg (2,645 lbs).

Intralogistics solutions that drive the automotive industry forward

Solutions portfolio

You too can profit

Your Contact Person: Robert Luxenhofer

You would like to know what Grenzebach intralogistics solutions can do for you? Call or write us about your challenge. We look forward to hearing from you!